Computer tomography (CT)

Jeden z naszych stałych Klientów zauważył wyciek cieczy z przewodów aluminiowych.

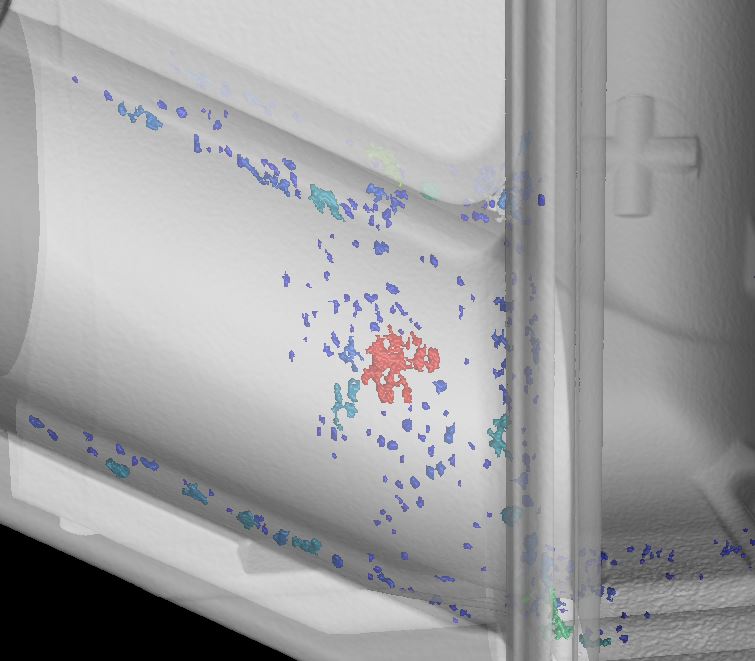

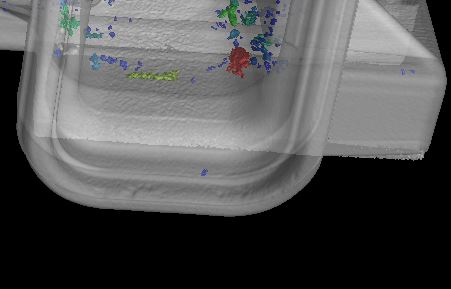

Computed tomography in industry facilitates the production of a 3D model of the component under study. The image shows both the external and internal areas of the component.

Industrial computed tomography – is the process of creating a three-dimensional visualization of the detail on the basis of several thousand X-ray images. It is performed on industrial machines containing special software that allows the merging of images.

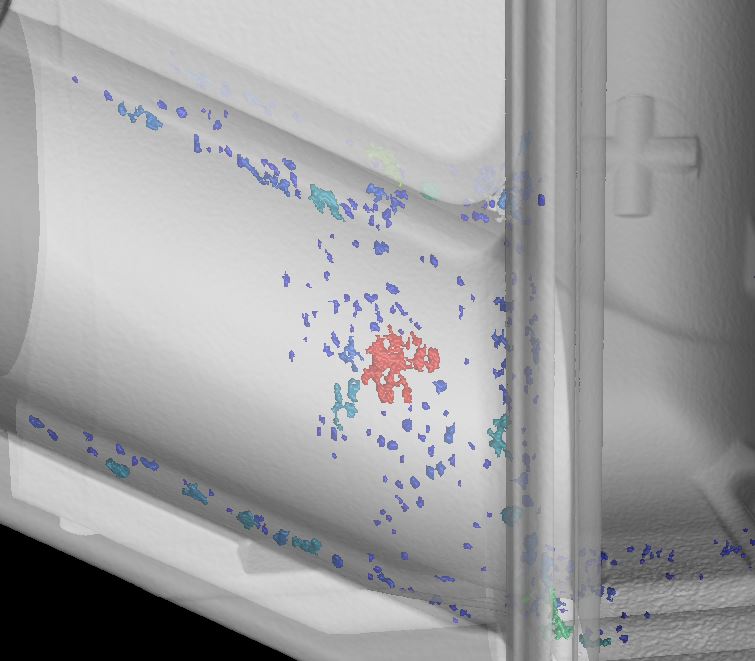

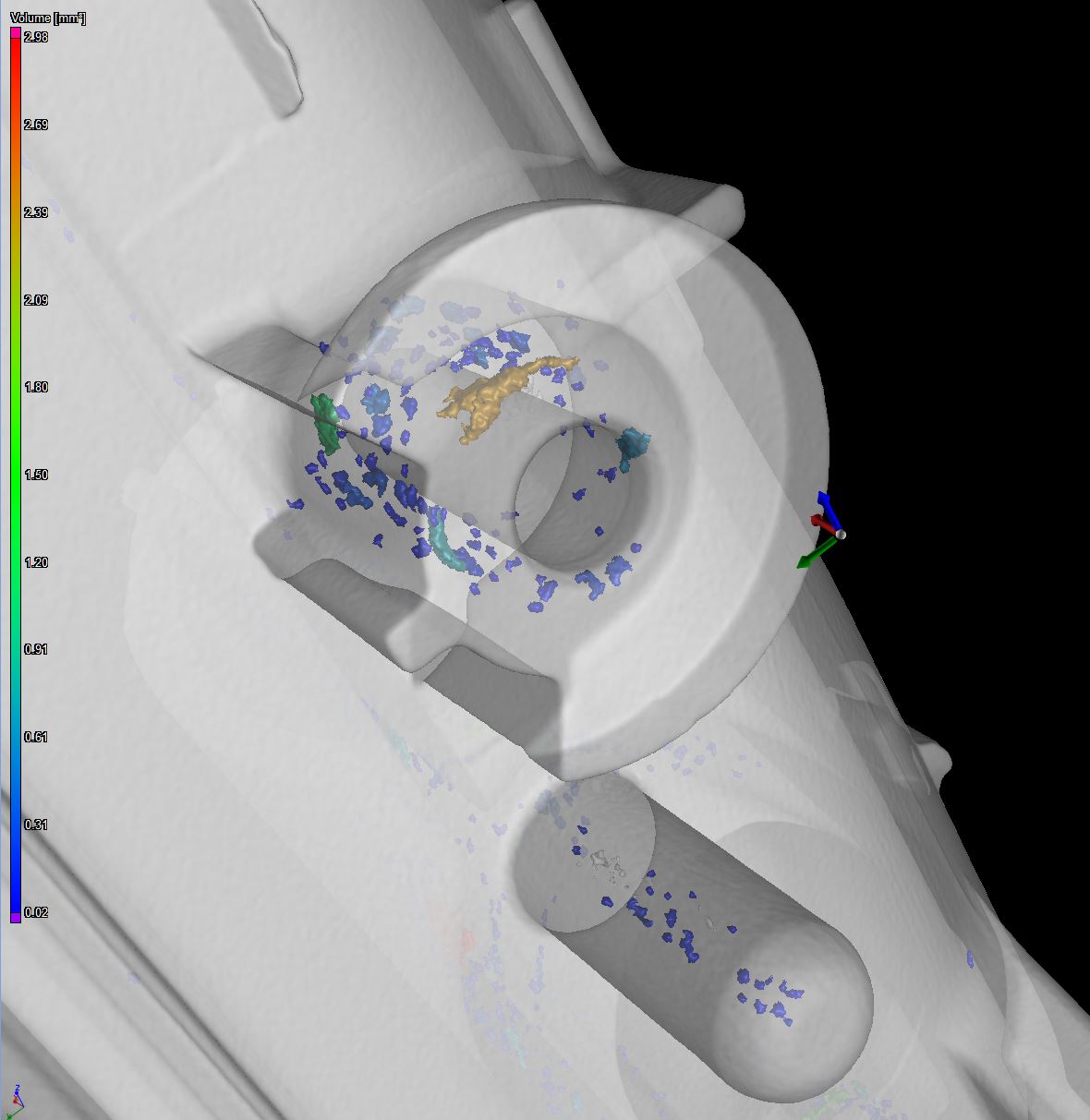

With the created 3D model, one can see the entire detail on the outside and inside, which is very helpful in porosity analysis, checking the correctness of assemblies, searching for gaps between internal details, detection and analysis of porosity in welds, solders and detects many other defects in the details.

By using professional software VGStudio, it is possible to inspect details with full analysis, reports, obtaining information on defects and details.

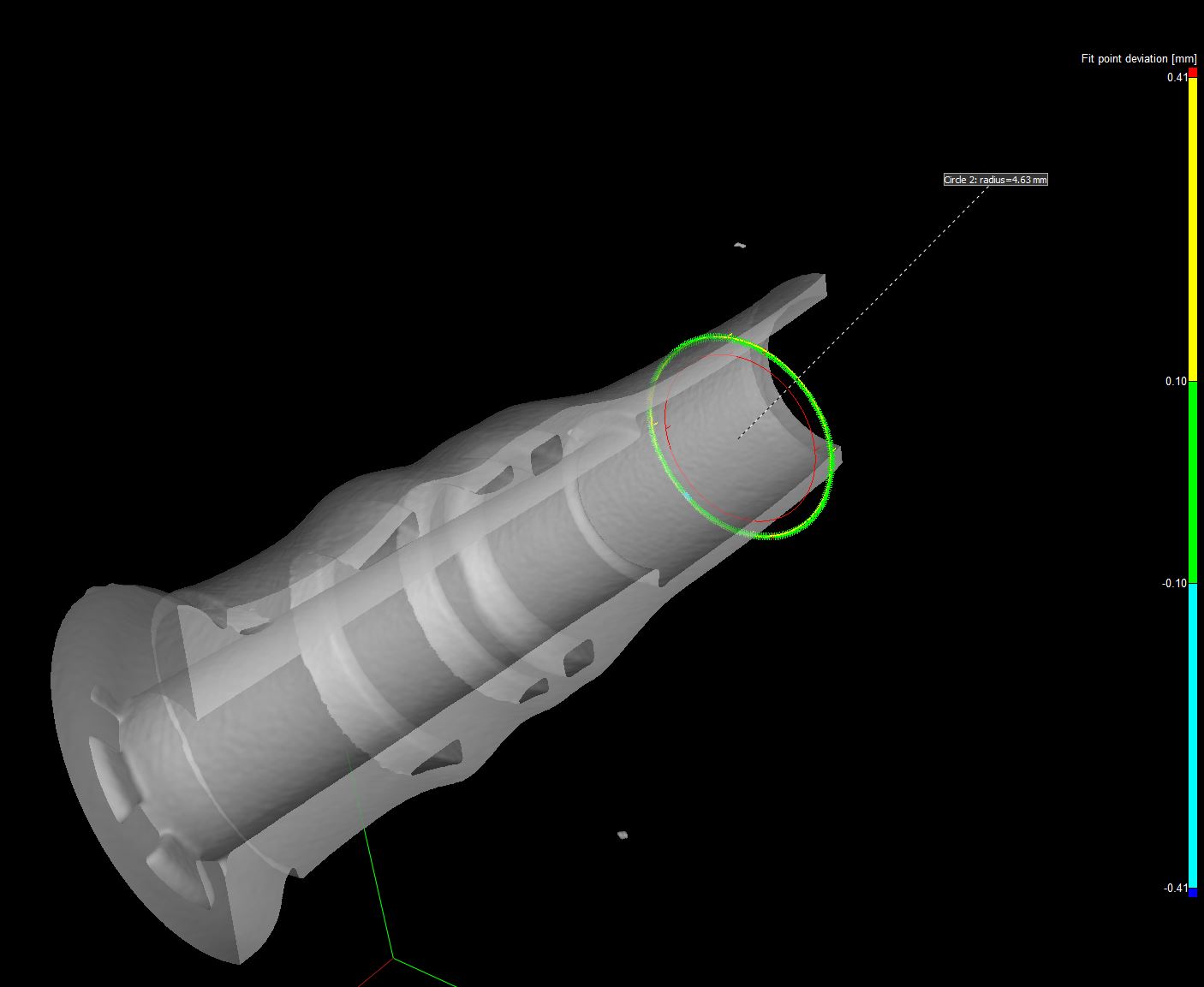

If we have an additional CAD model, with using a color grid we can present deviations of the examined detail from the assumptions of the drawing. It is also possible to perform a full dimensional analysis based on the technical drawing of the detail.

Marcin Cygan

Technical and Sales Advisor

+48 577883677

marcin.cygan@sgpgroup.eu

There is no detail that could not be put under inspection. We offer a high-class software, used for the visualisation and data analysis obtained from the computer tomography.

Computed tomography is a modern field of metrology and non-invasive testing performed using XCUBE X-ray.

By using the computer tomography in order to examine the detail saves time and boasts effectiveness of production.