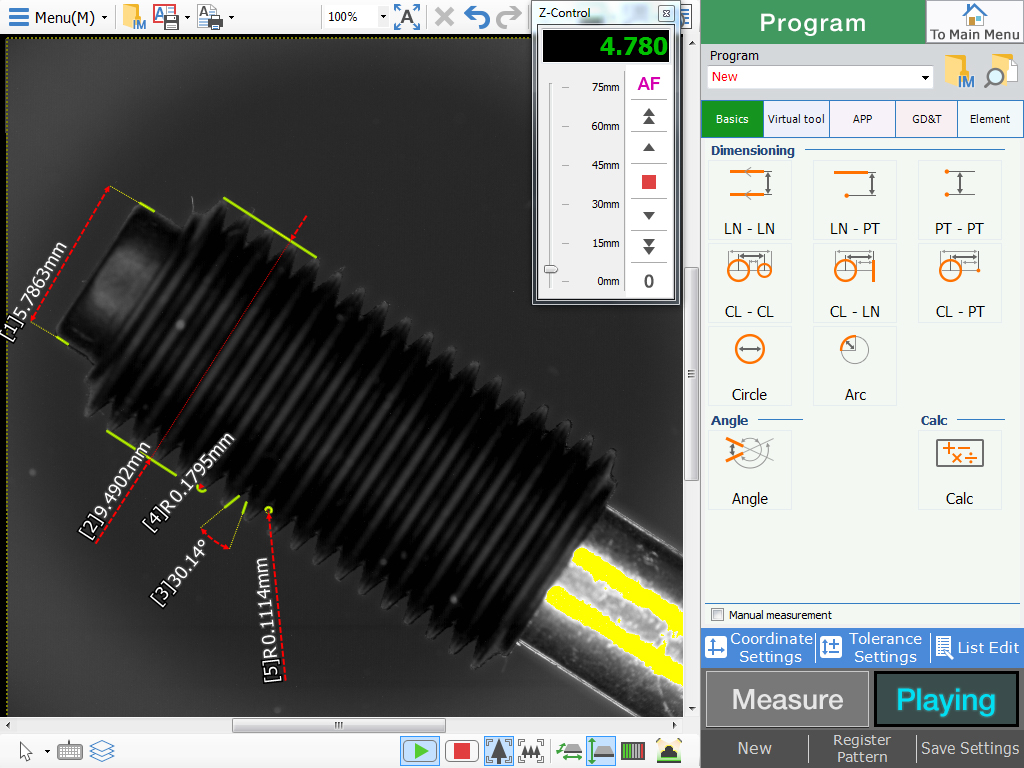

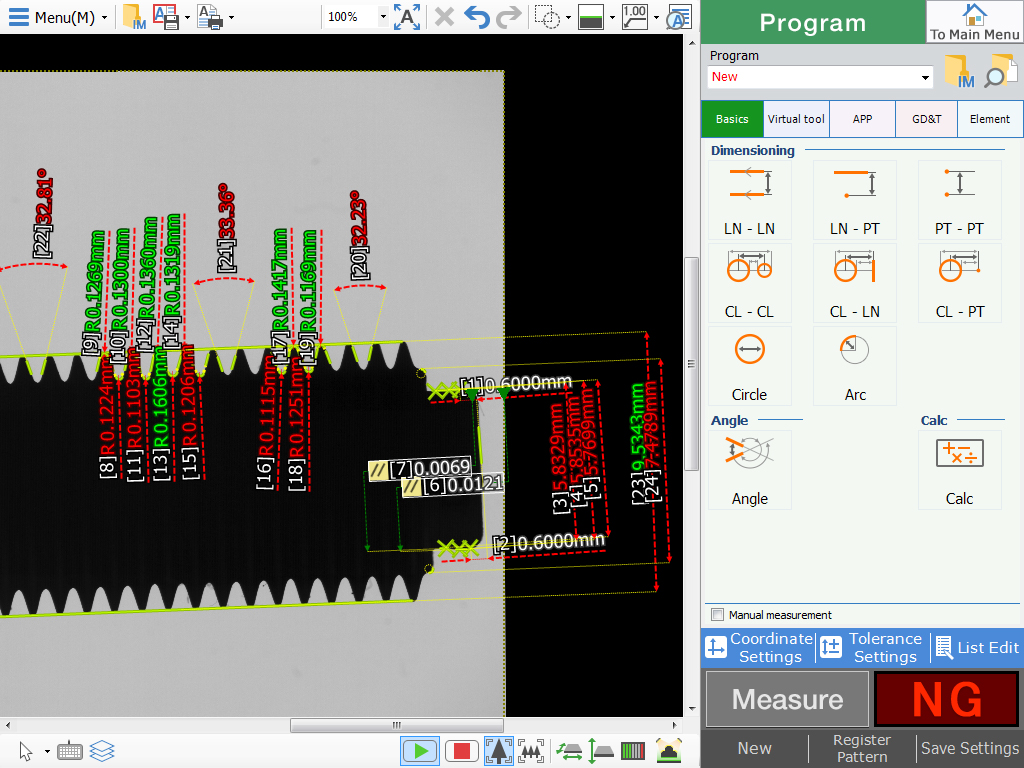

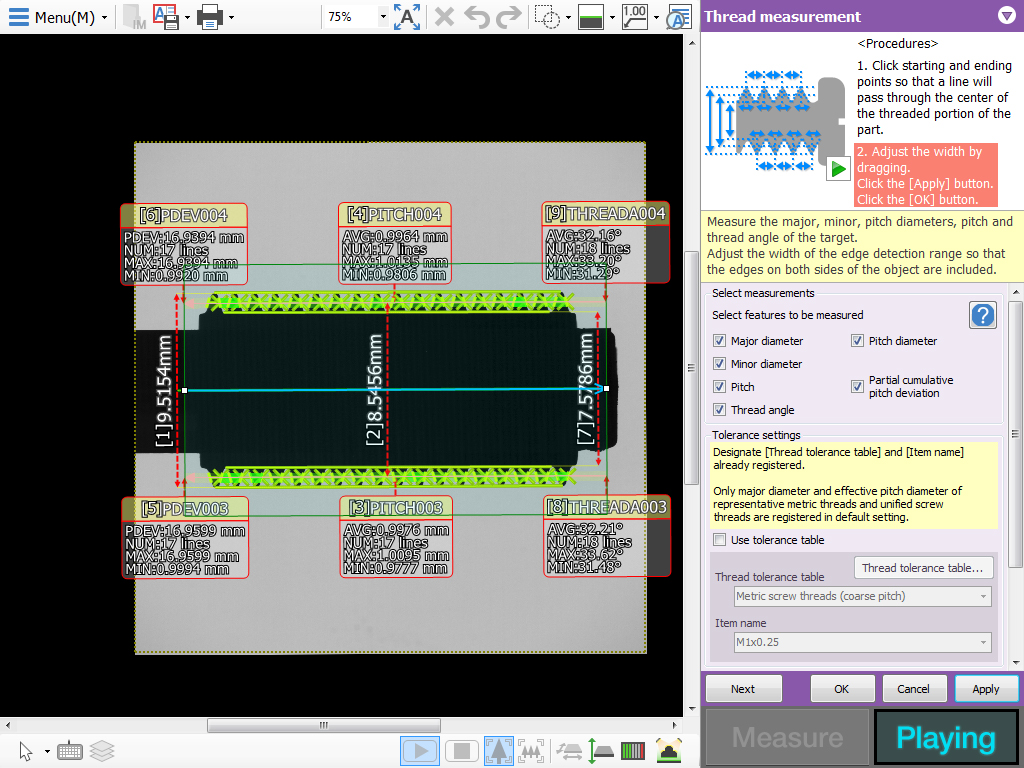

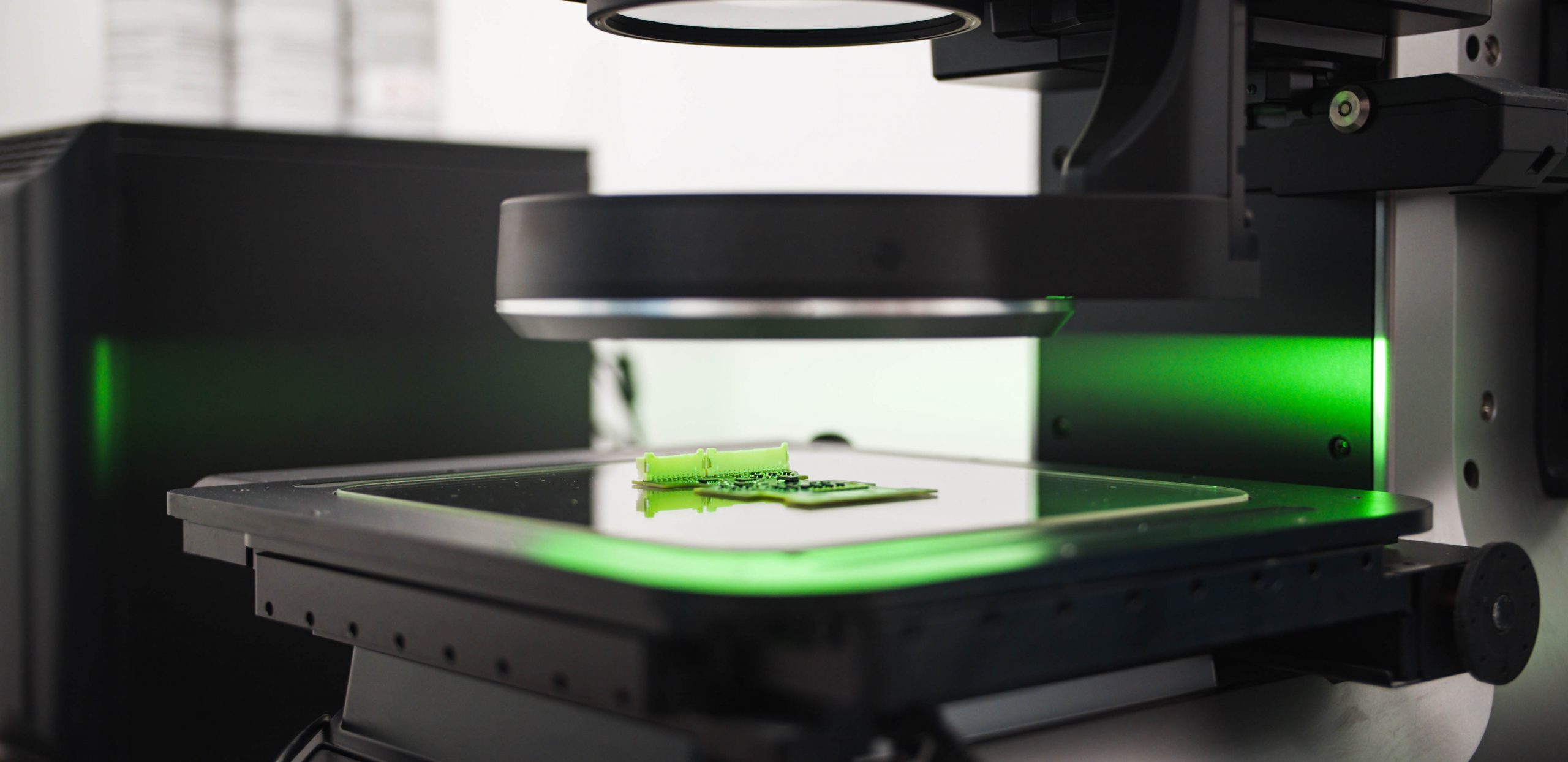

Usage of visual comparator for customer’s problem solving

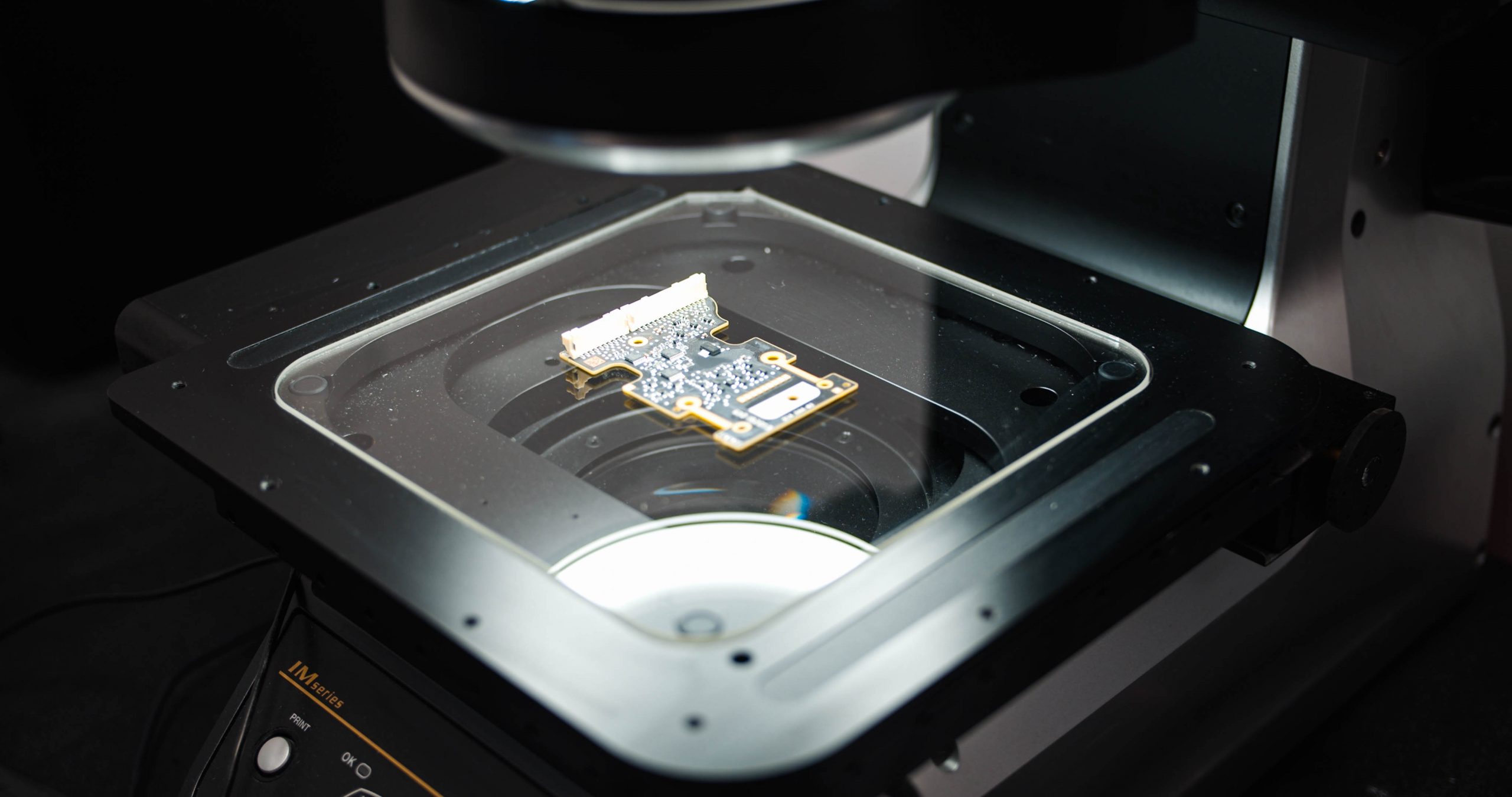

A new customer observed a dimensional inconsistency of the rivets used in the production process. Wanting to quickly inspect and separate incompatible elements, he reported to SGP Quality Lab. The best solution to this problem was digital analysis.