Biorąc pod uwagę dynamikę przemysłu oraz rosnące normy wydajności i trwałości produktów oferujemy zaawansowane usługi kontroli jakości. Jesteśmy specjalistami w zakresie badania mikropęknięć elementów oraz automatycznej kontroli jakości. Możemy skutecznie wyeliminować błędy produkcyjne, zanim te trafią do klienta. Przy użyciu efektywnego systemu kontroli jakości pomagamy firmom zwiększyć wydajność poprzez optymalizację procesów produkcyjnych.

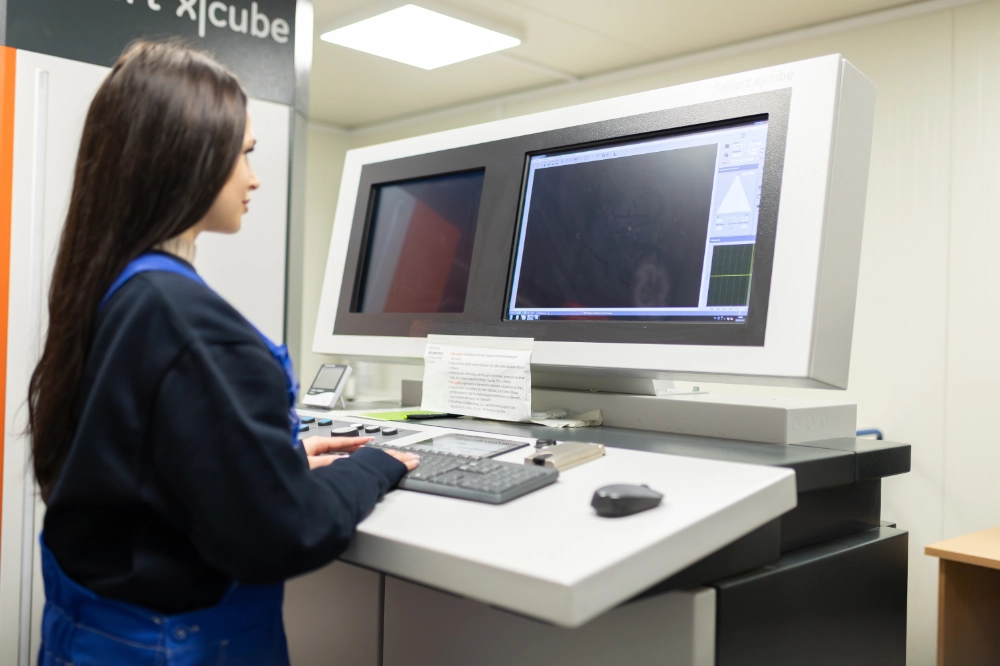

Bezdotykowa kontrola jakości – wydajność i precyzja

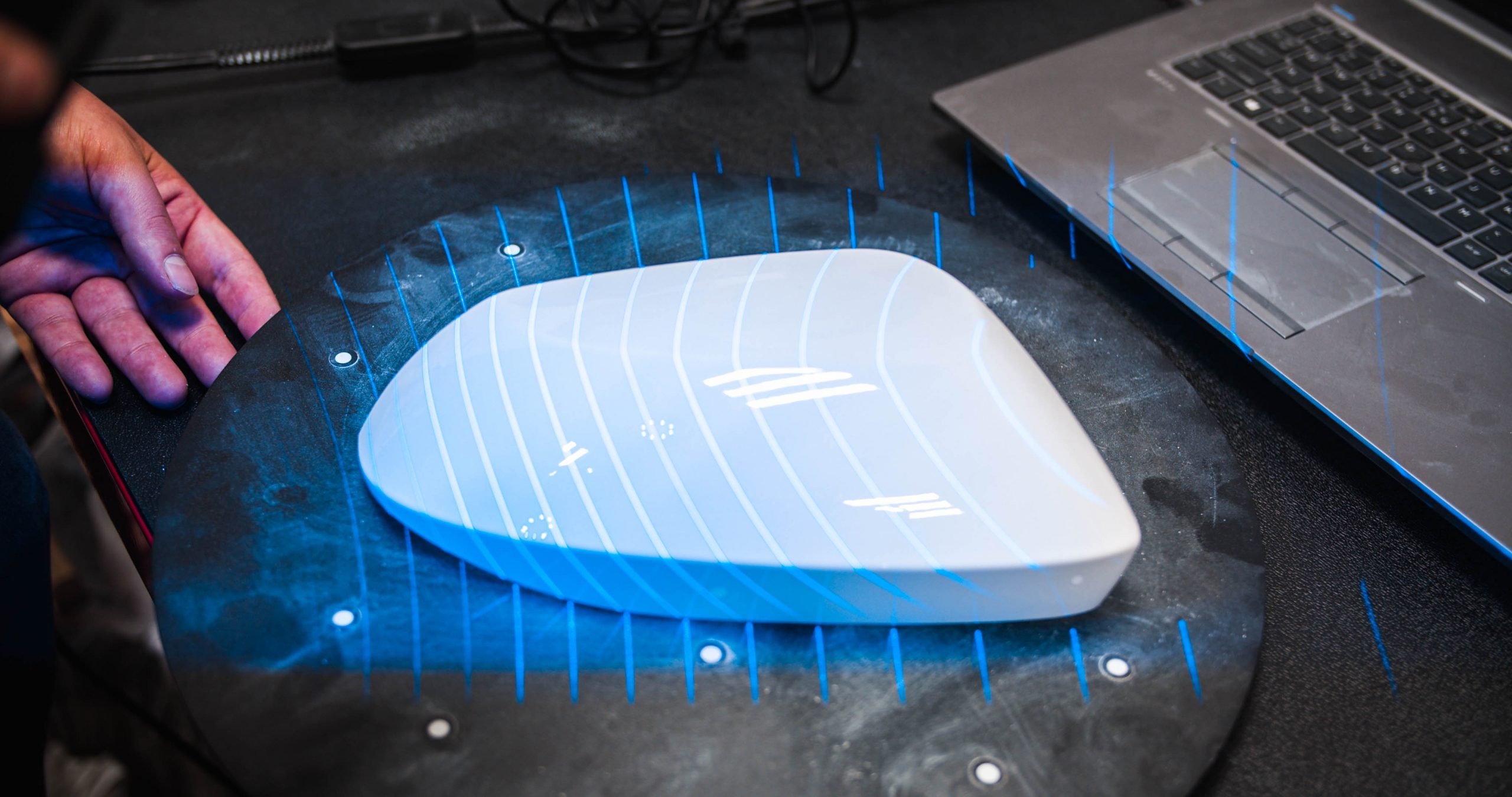

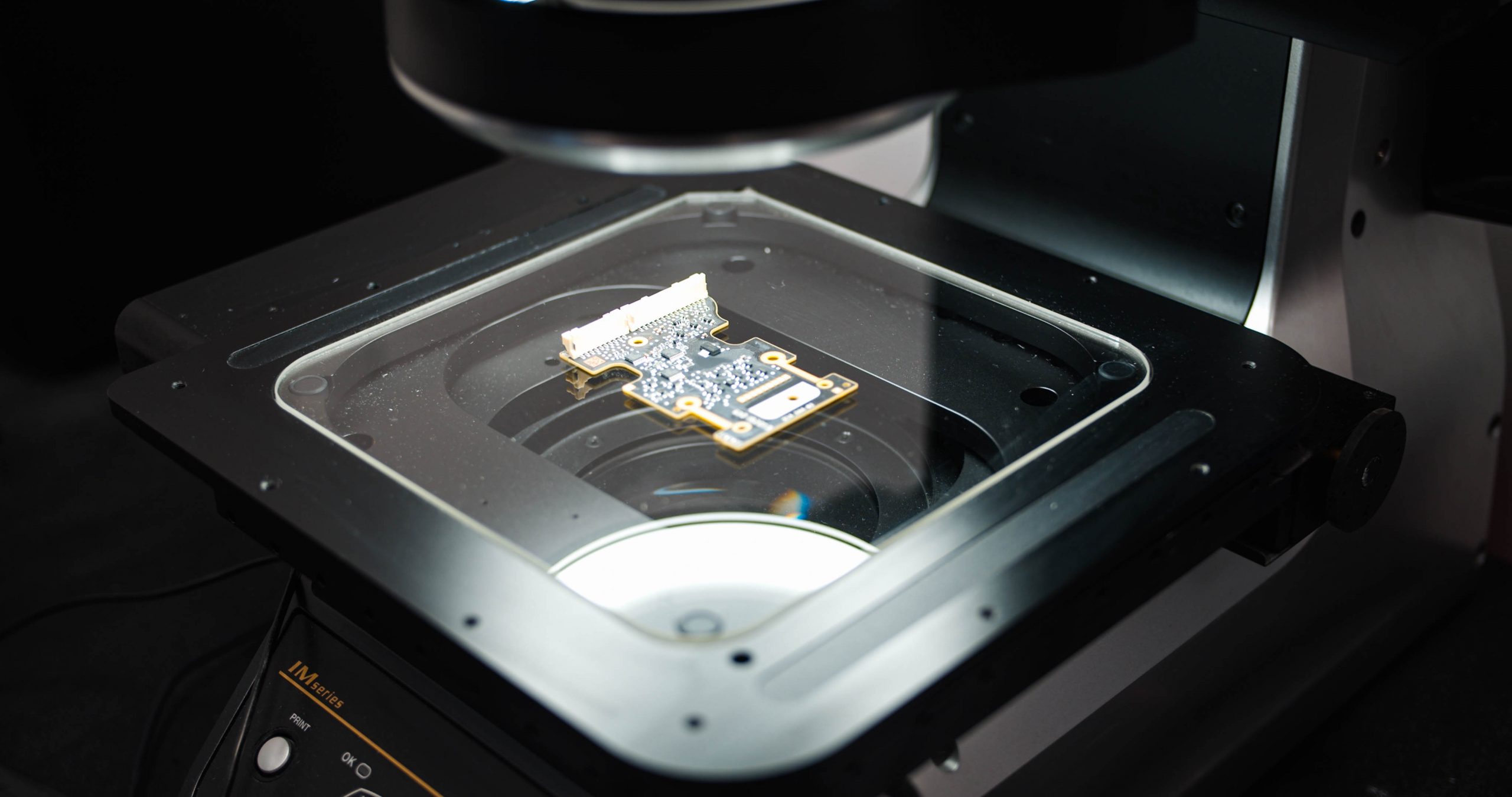

Główna zaleta naszego systemu kontroli jakości to przede wszystkim oszczędność czasu i mocy produkcyjnej, które zapewniają badania nieniszczące wykonane przez naszą firmę. Dzięki możliwości analizowania elementów w czasie rzeczywistym możemy szybko wykryć ewentualne nieprawidłowości. Zadanie to ułatwia zaawansowana bezdotykowa kontrola jakości, która jest nieinwazyjna dla sprawdzanych elementów.

Badania nieniszczące – jakość potwierdzona praktyką

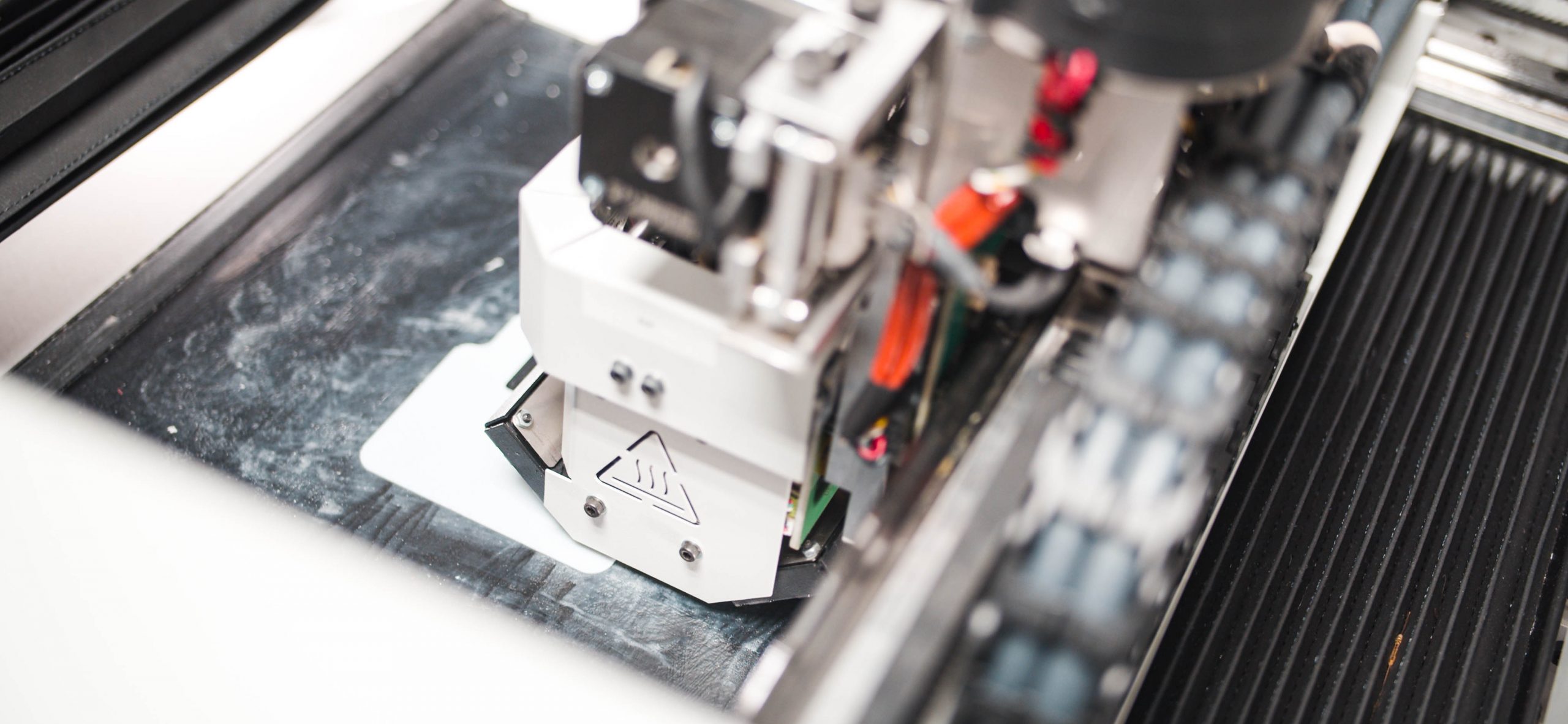

Wykorzystujemy różne rodzaje badań nieniszczących. Pozwala to na dokładne sprawdzenie wytrzymałości materiałów, a także na wykrycie ewentualnych defektów niewidocznych gołym okiem. W naszym portfolio znajdują się między innymi badania mikropęknięć elementów, które są kluczowe dla zapewnienia bezpieczeństwa.

Rodzaje Kontroli Jakości – dostosowane do Twoich potrzeb

Oferujemy kontrolę jakości przemysłowej, technologicznej oraz laboratoryjnej. Skupiamy się na usługach z zakresu kontroli jakości, sortowania, naprawy detali i komponentów oraz wyrobów gotowych. Przeprowadzamy precyzyjne badania jakościowe, co umożliwia bezbłędne wykrycie wszelkich potencjalnych nieprawidłowości. Dostarczane przez nas usługi są na najwyższym poziomie. Korzystamy z zaawansowanych maszyn, które dzięki precyzyjnym działaniom umożliwiają nam otrzymywanie bardzo dokładnych wyników badań.

SGP Quality Lab – Twój partner w kontroli jakości

Nasza firma to renomowane centrum jakościowe zapewniające badania nieniszczące przy wykorzystaniu najnowszych technologii. Zapewniamy usługi, które sprawią, że Twoje produkty będą zawsze spełniały wszystkie normy jakości. Gwarantujemy:

- poprawę wydajności produkcji;

- zwiększoną trwałość produktów;

- zredukowanie kosztów związanych z błędami produkcji.

Zaufaj naszym ekspertom! Postaw na współpracę ze sprawdzonym dostawcą, gwarantującym elastyczność oraz wysoki poziom usług.