The problem of leaks in assembled hydraulic units

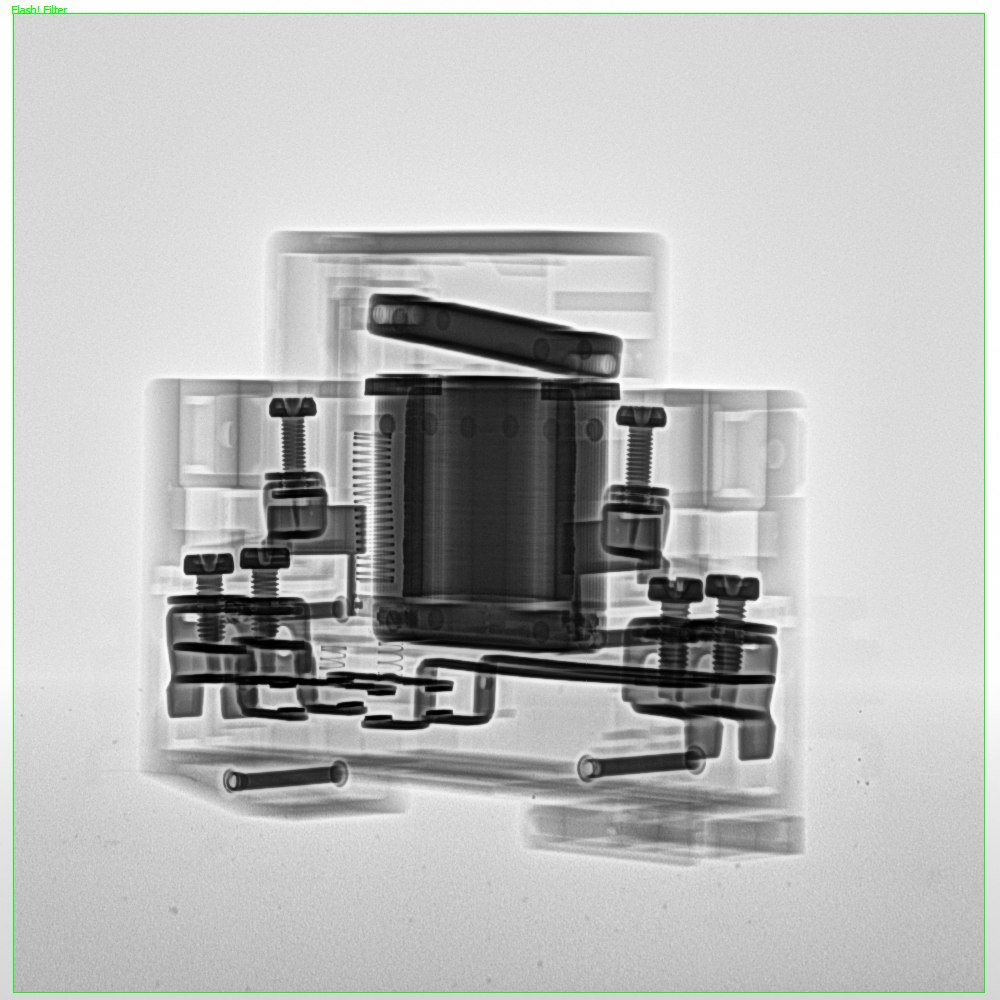

A customer approached SGP Quality Lab with a leakage problem in assembled hydraulic components. After analyzing his own manufacturing process, he could not find any cause lying on his side, so he asked us to help him solve the problem.