CNC Milling

A customer approached us in search of a contractor capable of executing their CNC machining project more affordably and quickly. After analyzing various market offers, they concluded that SGP Quality Lab is the best choice.

CNC machining is one of the most effective cutting methods, enabling precise and efficient processing of parts.

Our machine park is equipped with advanced machining centers, high-quality tooling, and measurement systems. They allow for the production of components with high quality and repeatability.

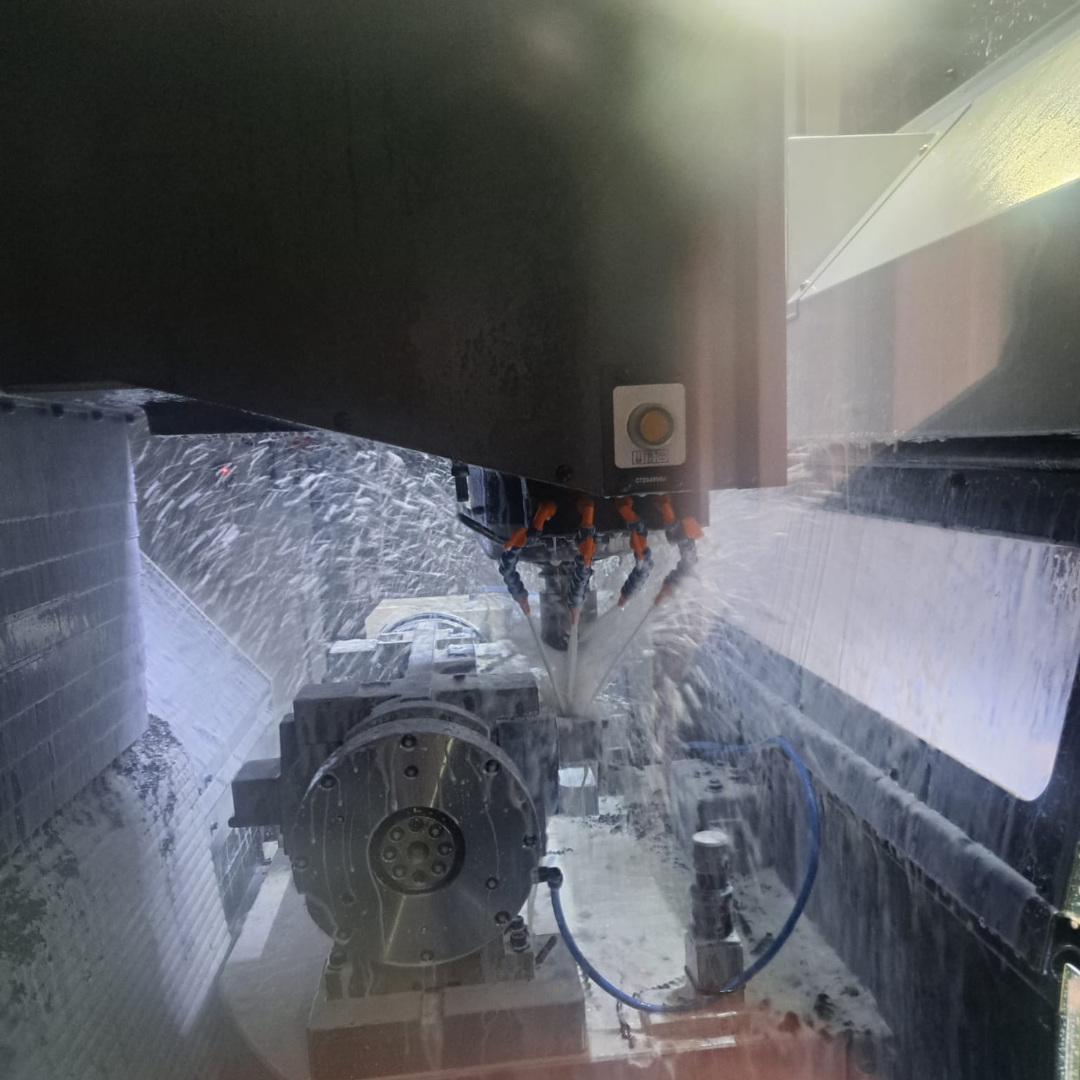

Thanks to milling machines with rotary tables and a fourth axis, we reduce machining time and offer the capability to produce even the most complex parts.

Lathes with bar feeders and catch spindles enable automatic operation.

We specialize in serial and mass production, but we also handle individual orders—always with an emphasis on quality and punctuality.

We machine:

Marcin Cygan

Technical and Sales Advisor

+48 577883677

marcin.cygan@sgpgroup.eu

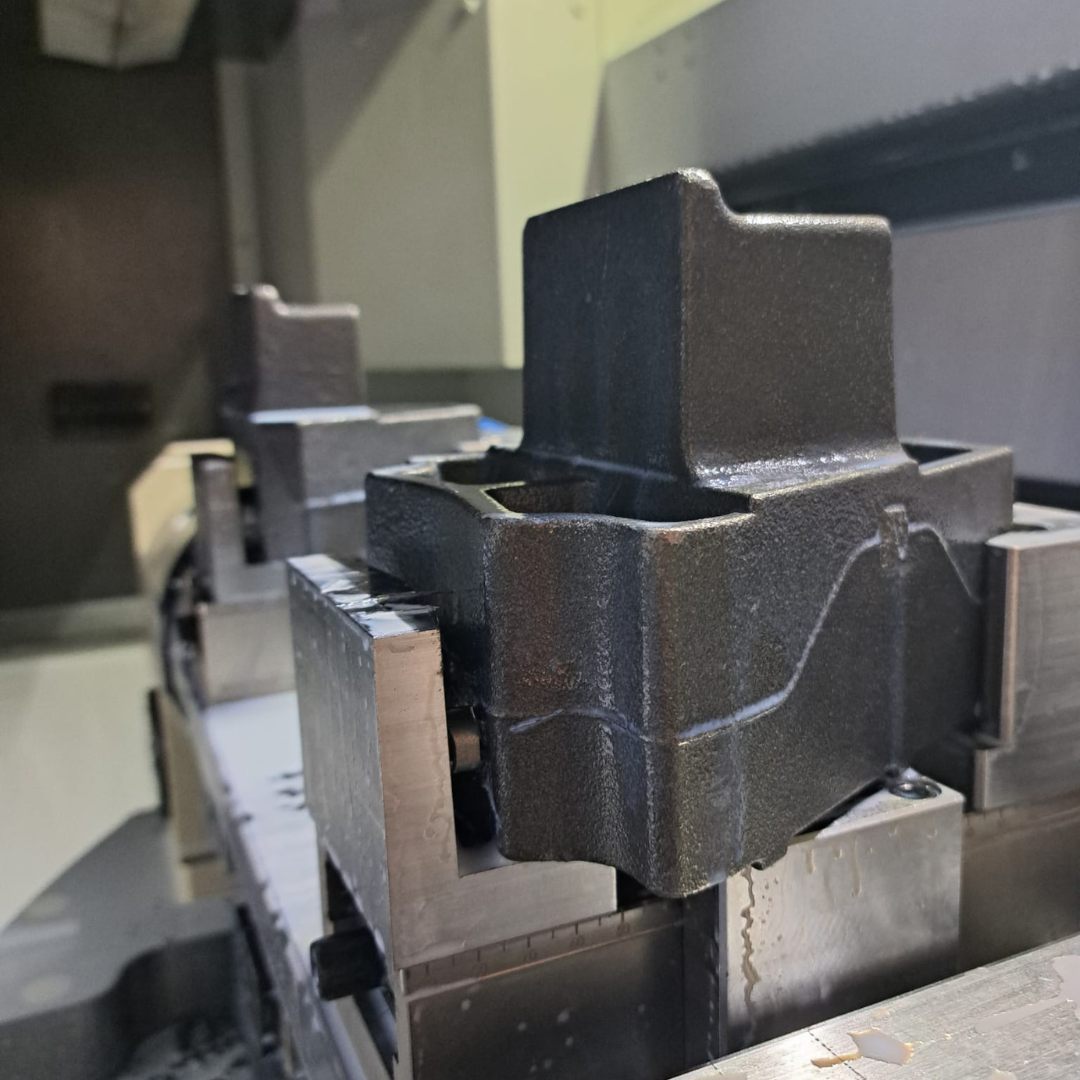

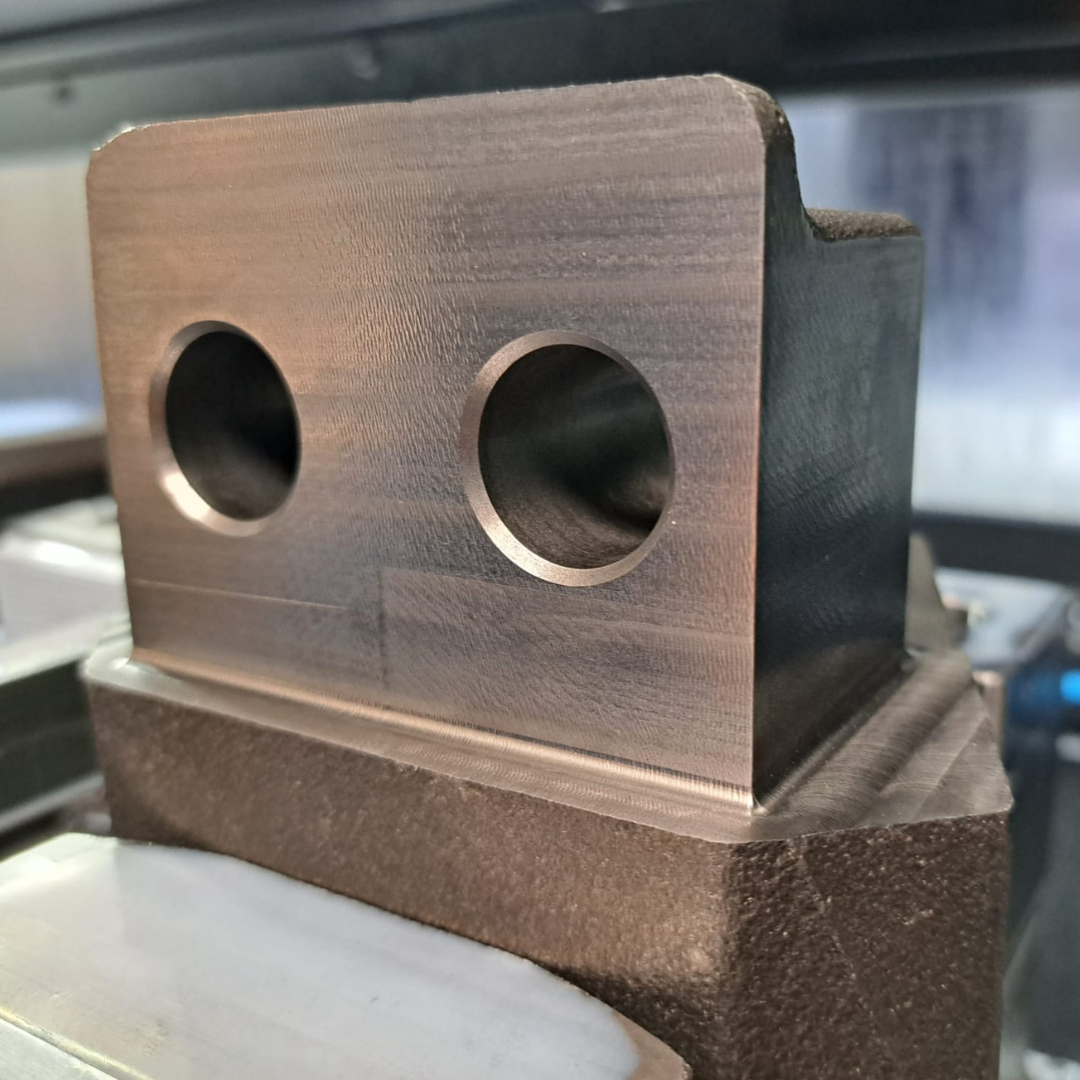

The capabilities of the workpieces we process are demonstrated in the ensuing pictures. The finished items, which are shown in the final shot, demonstrate the high quality of the processed surfaces while cutting down on processing time.