The Importance of Electronics in Cars

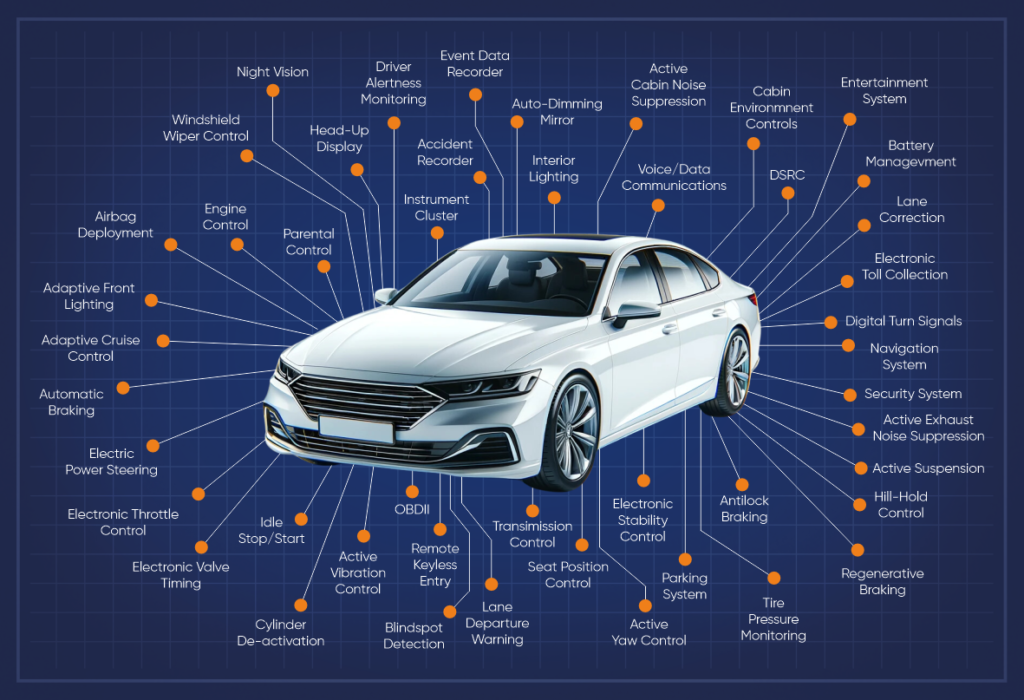

Contemporary cars are technologically complex machines in which advanced electronics play a crucial role, underscoring their necessity across a broad spectrum of applications. From engine management systems, through advanced traction control systems, to innovative electronic braking mechanisms – each of these elements utilizes digital technology to enhance safety, efficiency, and driving comfort. Additionally, advanced infotainment systems transform vehicles into mobile communication centers, offering passengers not only entertainment through access to multimedia and the Internet but also providing key navigational and telematic information, making them an integral part of modern mobility.

Furthermore, modern cars use between 1000 to 1400 semiconductor circuits, indicating their complexity and high degree of technological advancement. These circuits are scattered throughout the vehicle, from engine management systems, through safety systems, to comfort and entertainment modules. Their presence emphasizes the evolution of cars from mechanical structures to intelligent machines capable of making autonomous decisions based on data from multiple sensors and systems.

The cost of all the electronic equipment in a new passenger car often exceeds 40% of the vehicle’s value, which not only testifies to the importance of electronics for contemporary automotive but also its impact on production costs, final price for consumers, and on the overall design and functionality of the vehicle. This growing dependency on electronics also highlights the importance of continuous research and development in the field of automotive electronics, to ensure the highest levels of safety, energy efficiency, and user comfort.

Therefore, the development and integration of advanced electronic systems in cars are not just a trend but a necessity that defines the direction of future innovations in the automotive industry. With them, it is possible not only to improve traditional vehicle functions but also to introduce entirely new possibilities, such as autonomous driving, remote vehicle control, or advanced driver assistance systems, opening new perspectives for the future of motoring.

pic 1. Electronic systems in modern cars

The Use of X-Ray Technology in Quality Control of Automotive Electronics

The application of X-Ray technology in the quality control of automotive electronics components is a crucial element in maintaining high quality standards in the automotive industry. This advanced diagnostic method, allowing for the non-invasive examination of the internal structure of components, is invaluable for car manufacturers and suppliers in identifying and addressing potential problems early in the production or even design process.

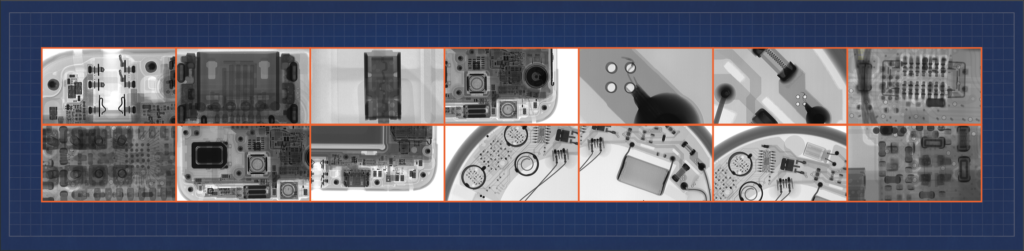

X-Ray technology, also known as radiography in conjunction with computed tomography (CT), allows for detailed visualization of internal material structures without the need for physical disassembly or destruction. This method is particularly useful in the quality control of automotive electronics, including printed circuit boards (PCBs), microconnectors, wiring harnesses, and other key electronic components. It enables the detection of various defects, including:

- Micro-cracks and cracks in component casings, which can affect their durability and functionality.

- Soldering issues, such as cold solder joints or voids in soldered connections, which can weaken electrical conductivity and reliability of connections.

- Misplacements of electronic elements, which can lead to device malfunction.

- Shorts and breaks in conductive paths, crucial for the proper functioning of automotive electronics.

Technology and Inspection Methodology

The technology and inspection methodology based on the use of X-Ray radiation is a key element of modern control processes, especially in the context of electronic component analysis. This advanced inspection method allows for the penetration of objects using X-Ray radiation, which is absorbed to varying degrees by materials of different densities. This enables the creation of contrasted images of the internal structures of the component under examination, allowing for precise analysis of its condition and the identification of potential defects. With technological evolution, modern X-Ray inspection systems utilize both two-dimensional (2D) techniques and three-dimensional computed tomography (3D CT). Computed tomography is particularly valuable as it allows for the creation of detailed three-dimensional reconstructions of components’ internal structures.

pic 2. Example realizations of electronic components

Benefits of Using X-Ray Technology

The implementation of X-Ray technology in inspection processes brings several benefits that significantly improve the quality and reliability of manufactured electronic components:

- Detection of Invisible Defects: X-Ray technology allows for the identification of defects that are invisible to traditional inspection methods, such as visual or manual checks.

- Increased Speed and Accuracy of Inspections: Thanks to the automation of image analysis processes, it is possible to significantly speed up control processes while simultaneously increasing their accuracy.

- Optimization of Production Processes: Rapid identification and elimination of defect causes allow for the optimization of production processes, reducing time and costs associated with quality control.

- Increased Reliability and Durability: By early detecting and eliminating potential defects, X-Ray technology contributes to increased reliability and durability of electronic components, which directly translates into the quality and safety of final products, including vehicles.

Conclusions

The integration of X-Ray technology in the automotive sector highlights the pursuit of excellence and is a strategic step for manufacturers in offering high-quality and reliable vehicles. It is key to building market position and gaining customer trust, leading to commercial success. Supporting this goal, SGP Quality Lab provides X-Ray inspection service for both individual orders and serial production, enabling effective quality control. Advanced technologies and the experience of SGP Quality Lab ensure accurate defect detection, raising the quality and competitiveness of products.

author: Łukasz Ciechowski – Quality and Development Manager